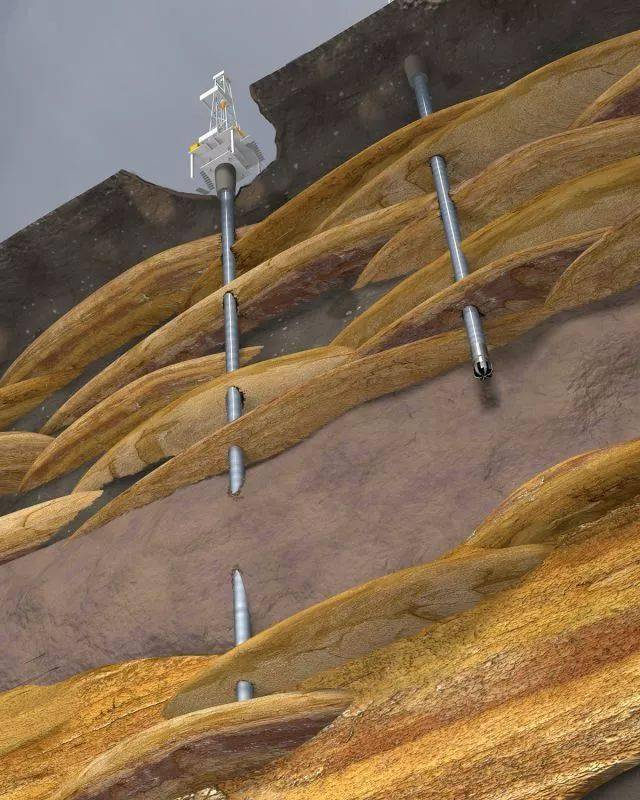

In today’s fast-paced drilling environments—whether in energy, mining, or construction—efficiency, precision, and durability are non-negotiable. One tool is redefining drilling performance: the PDC (Polycrystalline Diamond Compact) drill bit.

While TC (Tungsten Carbide) bits have served the industry well for decades, PDC drill bits are increasingly the preferred choice thanks to their superior cutting mechanism, extended lifespan, and performance in challenging applications.

What Makes PDC Drill Bits So Effective?

PDC drill bits feature a synthetic diamond layer fused to a tungsten carbide substrate. This ultra-hard surface allows the bit to shear through formations rather than crush them, resulting in faster, smoother, and more consistent drilling.

PDC drill bits Key Advantages:

Faster ROP (Rate of Penetration) in soft to medium formations

Longer service life due to exceptional wear resistance

Lower total cost per foot drilled

Reduced downtime with no moving parts to fail

Ideal for directional drilling thanks to consistent tool face control

Comparison: PDC vs TC Drill Bits

| Feature | PDC Drill Bits | TC Drill Bits (Tungsten Carbide) |

|---|---|---|

| Material | Synthetic diamond layer on tungsten carbide substrate | Solid or insert-based tungsten carbide |

| Cutting Structure | Fixed cutter (no moving parts), shears rock | Typically roller cone, crushes, and grinds rock |

| Hardness | Extremely hard (due to the diamond layer) | Very hard, but less than a diamond |

| Durability | Excellent in soft to medium formations | Good in hard, abrasive formations |

| Drilling Speed | Fast – especially in homogeneous formations | Slower, especially in hard formations |

| Shock Resistance | Less tolerant to impact and vibration | High shock and impact resistance |

| Repairability | Limited repairable | Often rebuildable or repairable |

| Cost | Higher upfront cost | Lower to moderate cost |

| Applications | Oil & gas, geothermal, mining – soft to medium-hard rock | Mining, construction, geothermal – hard & abrasive rock |

| Formation Suitability | Best for soft, clay-rich, or shale formations | Best for hard, abrasive, and fractured formations |

Why More Drillers Are Switching to PDC

While TC bits offer rugged durability, especially in extremely hard or fractured rock, PDC bits excel in 80% of common drilling scenarios, particularly where speed and precision matter. From oil & gas wells to geothermal energy and mining, PDC bits offer:

- Faster project completion

- Lower operational costs

- Fewer bit trips

- Better borehole quality

For companies looking to optimize both performance and ROI, PDC drill bits offer unmatched value.

Case in Point: PDC for Oil & Gas and Geothermal

PDC bits have become the standard for horizontal and directional drilling in oil & gas fields. Their shearing action reduces torque and vibrations, making them ideal for high-precision well paths. In geothermal projects, their heat resistance and extended life reduce the need for costly bit changes.

Explore Our PDC Drill Bit Solutions

Looking for reliable, high-performance PDC drill bits? Our range includes designs tailored for:

- Soft shale and sandstone formations

- Long-run horizontal wells

- Geothermal and mining applications

👉 Browse our full range: View PDC Drill Bits

While both PDC and TC bits have their place, the advantages of PDC drill bits are clear in most modern drilling environments. They deliver faster drilling, reduced costs, and longer service life—key factors that give your operations a competitive edge.

Ready to upgrade your drilling performance?

Contact our experts today to find the right PDC bit for your formation and drilling goals.

E-mail: info@pdcdrillsolution.com

Whatsapp: +8618974966967