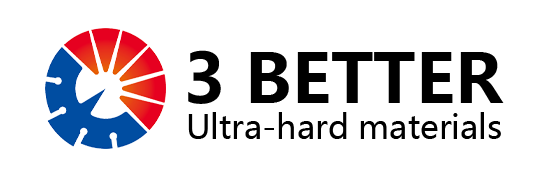

Tungsten Carbide Hardfacing PDC Bits are premium drill bits engineered for the most challenging and abrasive formations. They integrate high-grade, thermally stable PDC cutters, specifically designed to maintain their sharpness and integrity in hard, interbedded rock.

The strategic application of tungsten carbide hardfacing on the gauge and body provides superior protection against catastrophic abrasive wear. This synergy between advanced cutters and extreme wear resistance ensures consistent performance, exceptional durability, and reliable steerability in demanding drilling applications.

Available Sizes:

| Diameter (mm) | Diameter (inches) | Connection Type | Wings | Applicable Formations |

| 51 | 2” | API Regular | 3 | Soft to Medium Formations |

| 76 | 3” | API Regular | 3 | Soft to Medium Formations |

| 102 | 4” | API Regular | 3/4 | Soft to Medium Formations |

| 127 | 5” | API Regular | 3/4 | Medium to Hard Formations |

| 152 | 6” | API Regular | 3/4 | Medium to Hard Formations |

| 171 | 6 3/4” | API Regular | 3/4/5 | Medium to Hard Formations |

| 191 | 7 1/2” | API Regular | 3/4/5 | Medium hard to Hard Formations |

| 216 | 8 1/2” | API Regular | 4/5/6 | Medium hard to Hard Formations |

| 244 | 9 5/8” | API Regular | 4/5/6 | Medium hard to Hard Formations |

| 311 | 12 1/4” | API Regular | 4/5/6 | Abrasive to Hard Formations |

| 350 | 13 3/4” | API Regular | 4/5/6 | Abrasive to Hard Formations |

Note: The above specifications are for users to choose. At the same time, different specifications of products can be produced and processed according to the requirements

Advantages:

1. Exceptional Gauge Protection:

It drastically reduces gauge wear, maintaining full hole diameter and ensuring drilling accuracy.

2. Extended Bit Life:

The hardfacing shields the bit body from abrasive formation, significantly increasing its operational lifespan.

3. Enhanced Steering Stability:

By preserving the bit’s profile, it provides consistent directional control and reliability for complex well paths.

4. Superior Erosion Resistance:

It protects critical areas from the destructive scouring of high-velocity drilling fluid and cuttings.

5. Improved Cost Efficiency

The combination of longer life and consistent performance reduces trips and downtime, lowering the overall cost per foot.

Applications:

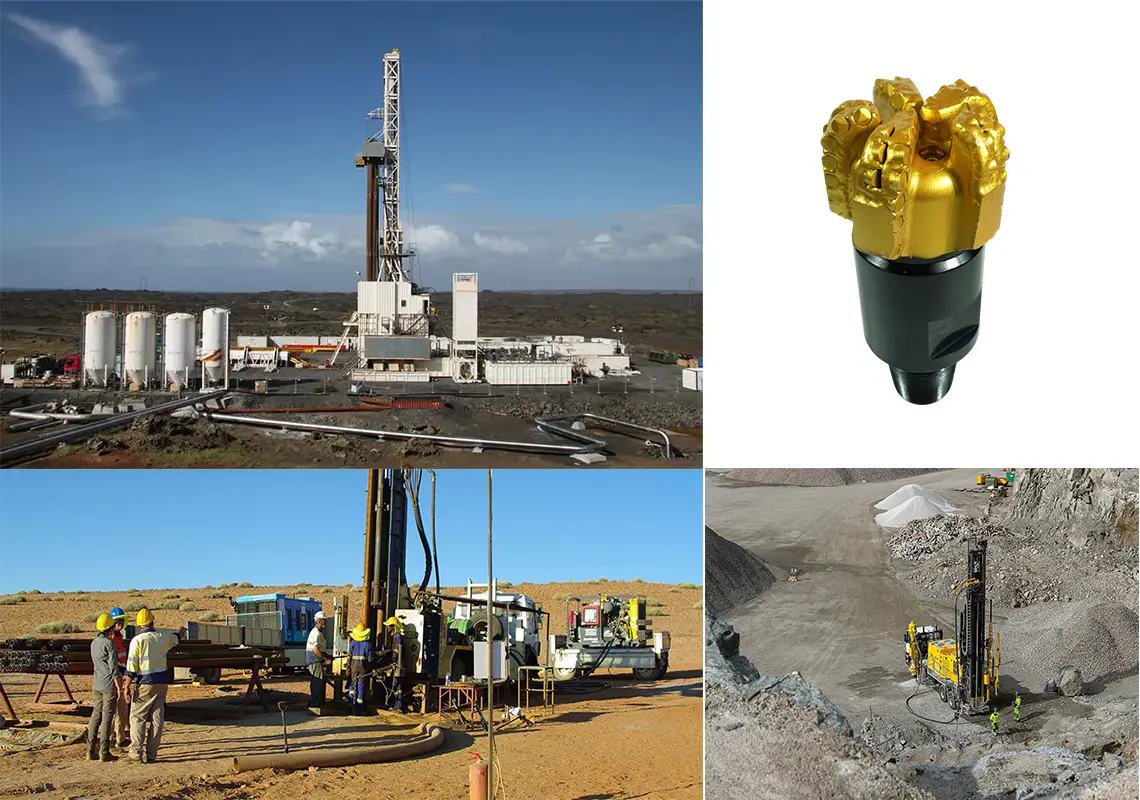

Hardfaced PDC bits are critical equipment in geothermal exploration, where they withstand extreme heat and highly abrasive volcanic formations.

In civil engineering and infrastructure projects, they excel at drilling through challenging mixed ground and reinforced concrete for foundation piling.

The mining exploration industry relies on them for their durability and longevity in penetrating hard rock layers for mineral sampling and blast hole drilling.

Furthermore, they are indispensable in geological exploration for obtaining intact core samples from deep, variable strata. Their robust wear resistance makes them the preferred choice for these demanding sectors, ensuring high efficiency.